|

FREQUENTLY ASKED QUESTIONS

What Should I Paint to get the Best Effect?

From all the information you have read so far, you have probably realised that we keep referring to the painting of the roof . We generally only refer to the painting of the roof because it is the part of the building that receives the greatest solar radiation heat loading. Sometimes there are other parts of the building that would also reduce the building heat loading if painted with Insulpaint ® , for example a large external wall that for most of the day is exposed to the sun. With a little help from your Insulpaint ® distributor you will be able to determine what would be the best surfaces to paint to achieve the greatest reduction in heat loading.

How Thick is The Insulpaint ® Applied?

Generally the Insulpaint ® is applied to a wet film thickness of 0.45 mm.

This Equates To Half a Litre Per Square Metre ie 200M2 Surface Requires 100Ltrs Insulpaint.

Who can Apply Insulpaint ® ?

Anybody who is a reasonable painter can apply Insulpaint ® , however the instructions must be carefully followed.

What Surfaces can be Painted with Insulpaint ® ?

Insulpaint reduces the internal temperature when applied to the external surfaces of the following substrates:

• Metal

• Tiles

• Brick

• Fibro Sheeting

• Concrete

• Timber

• ASBESTOS

What are some Ideal Insulpaint Applications?

Insulpaint dramatically reduces the solar radiation heat loading when applied to all surfaces such as,

• Roofs on Factories Houses,patios,sheds,Dog and cat kennels,ANY HOT SURFACE!

• Walls on the above and/Concrete Tilt Panels. Concrete Foundation Slabs.

• Site Offices/Metal/ Steel/Asbestos/Wood/ Fiberglass

• Portable Structures/BOATS/ Any surface material.

• Water Storage Tanks/ Wine Vats/HOT Pipes/Railings/Gates/Driveways/ Decking/Pools/Steps/Garage Doors/ Trailers.

How Does Insulpaint ® Compare to In Roof Space Insulation?

The diagram on the right shows two scenarios. The top scenario shows how a building with either no insulation or insulation applied in the roof space allows the entire roof space to heat up. This area can heat up to over 50 degrees Celcius on a hot day, requiring that the insulation within the roof work very hard to stop the area under the ceiling achieving the same temperature. If there is no insulation the temperature under the situation is even worse.

The lower scenario shows how the situation is different if the roof has been painted with Insulpaint ® .

Firstly, the light colour reflects a considerable amount of the heat load thus reducing the outside temperature of the roof. Secondly the insulating properties of the Acrad 8 prevent a lot of the heat passing from the outside of the coating to the inside. This results in a dramatically cooler roof space and under ceiling space. Additionally, because the roof space is cooler, when the outside temperature drops off the roof space does not continue to heat the building.

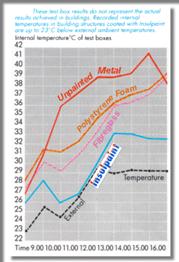

The diagram on the right shows results for Insulpaint ® when compared against the other conventional insulating systems.

Test metal boxes were insulated using the different systems and set outside in the sun. Temperature probes located inside the boxes measured the internal temperatures.

It can be seen that the Insulpaint ® treated box internal temperature was generally within three degrees of the ambient (external) temperature.

|

|

This result was far better than both the fibreglass and polystyrene foam insulating systems.

The very top trendline shows a box that was unpainted and uninsulated and reflects the very high temperatures that are achieved if no insulation is used. Remember that this test does not reflect the actual internal temperatures of a building, rather it compares the insulation effectiveness of different insulations.

|

|