|

What is Insulpaint ® ?

Insulpaint ® is a water based, high quality paint that is impregnated with a special proprietary ingredient called Acrad 8. The Acrad 8 gives the paint the unusual ability to block heat transfer from the outside of the coated surface to the inside. It is this ability that allows a reduction in the internal temperature of structures that are painted with Insulpaint ® . Many people ask What kind of temperature reduction could I expect if I paint my structure with Insulpaint and we cannot answer exactly, however you will be able to see from the following reference sheets that reductions in temperature can be as per client testimonials.

The added benefit to cooler temperatures is a structure that looks terrific and will continue looking great for a look time to come, a byproduct of using a high quality base paint. Insulpaint can be ordered in many different standard colours, and if you really want a particular colour that we don't already have, we can do that too! .

An important point to remember is that only Insulpaint ® has Acrad 8, and independent testing has proven Insulpaint ® with Acrad 8 is superior to all other insulating coatings. Some test cases follow at the end of these sheets to justify our claims.

A Summary of Why Insulpaint ® Is So Good at Doing Its Job

• Insulpaint ® reduces the Heat Load on buildings resulting in a lower Internal Temperature and can lower air conditioning energy use as per client testimonials. Insulpaint ® will keep on Looking Good for ten years Or MORE!!

• Insulpaint ® will work effectively for 10 years

• Insulpaint ® is TIME TESTED / INVENTED IN AUSTRALIA IN 1986 and PROUDLEY MADE IN WA BY CAMELEON PAINTS

• Insulpaint ® Recoat available after 10 years, for a Further 10 year guarantee.

Let's have a look at each of these characteristics in a little more detail:

Insulpaint ® reduces the Heat Load on buildings with the roof painted with it resulting in a lower Internal Temperature AND lower Air-conditioning Costs.

Insulpaint ® is a surface coating applied to exterior surfaces that prevents heat from passing into the building's interior. Insulpaint has been independently tested and conclusively proven to be more effective in reducing temperature than all other forms of insulation. While there are other heat insulating paints on the market, all of these use ceramic bead fillers to create their insulating quality. For a variety of reasons, ceramic beads don't perform as well as Insulpaint ® ' s exclusive ACRAD 8 formula, which has proven to reduce internal temperatures of metal roof buildings by around10 /15 DEGREES Whether it be a home or an industrial workshop, Insulpaint ® coated roofs significantly reduce the load and power requirement of air conditioning systems. Insulpaint ® clients in both extreme and normal conditions continue to report substantial reductions in energy costs after coating their roofs with Insulpaint ® . Independent testing by engineering & science consultants has confirmed what these clients had found through experience.

In full scale practical experiments, Insulpaint recorded a 30% to 60% saving in power costs, as shown in various specific test results and reports, such as Hamersley Iron, and our many and varied private homes and commercial client references. All this information is available at anytime. Please call 08-94027488.

Insulpaint achieves savings in power costs as per client and customer testimonials.

Insulpaint ® will keep on Looking Good.

Traditional heat reflecting paints use ceramic bead fillers, which within one year discolour and fade. The reason this occurs is because thousands of ceramic beads in the surface coating create an abrasive surface that collects dust and dirt through acid rain and pollution. Insulpaint ® on the other hand contains ACRAD 8, a fibrous insulating ingredient that helps Insulpaint ® retain a completely smooth surface. This surface facilitates the run off of dirt and grime, therefore avoiding discolouration. Insulpaint ® is also available in standard colours (with the option for custom tints), allowing you the choice of what will best suit your home or building.

If you really want that high gloss finish and even longer life, you can elect to coat over the Insulpaint ® with Insulglaze ® , an Acryline product that is clear and very robust, in that it stands up very well to abrasion and the elements, making it an ideal cover coat for Insulpaint ® .

Insulpaint ® will work effectively for the Life of the Coating.

With normal insulating paints, effectiveness is quickly lost when dirt build up reduces the reflecting qualities of a surface coating and acid rain breaks down the ceramic beads, causing the loss of the insulating air pocket. Insulpaint ® however continues to work effectively every year, having no discolouration in addition to having insulating fibres that don't break down. Insulpaint's 8 fibres are also protected by its 100% Styrene Acrylic resin, well known to be superior to all other acrylic resins in strength, durability and flexibility. Insulpaint's resin is completely impervious to airborne pollution & extreme weather conditions, and is also non flammable, non toxic and contains no hazardous fibres. Insulpaint ® is also completely waterproof, but at the same time is micro-porous, allowing the substrate to breathe, thereby avoiding cracking in masonry substrates.

Insulpaint ® is time tested and proven to Work.

After 30 years of commercial success, Insulpaint ® has stood the test of time and continues to amaze clients and researchers alike. Whilst Insulpaint ® ' s origins are based in WA, this high performance surface coating has now been applied to buildings throughout the globe, including, the Middle East, China , India , Japan and USA . At the request of both clients and government departments, independent testing has been conducted by the University of NSW , University of Bombay and dozens of research consulting firms, all of which have conclusively proved Insulpaint ® ' s exceptional heat reducing properties. Research reports and client testimonials are freely provided upon your request.

How Does Insulpaint ® Reduce Heat Loads ?

As explained earlier, Insulpaint ® is impregnated with a special proprietary ingredient called Acrad 8. Acrad 8 works like a batt type insulation in that it acts as a thermal barrier to prevent heat transfer through it. This insulating effect is preventing the conduction of heat through the coating ie the inside of the painted surface is cooler than the outside. If a light colour choice is made, the added benefit of light colours reflecting heat is also achieved. Let's have a look at how this works diagrammatically. As explained earlier, Insulpaint ® is impregnated with a special proprietary ingredient called Acrad 8. Acrad 8 works like a batt type insulation in that it acts as a thermal barrier to prevent heat transfer through it. This insulating effect is preventing the conduction of heat through the coating ie the inside of the painted surface is cooler than the outside. If a light colour choice is made, the added benefit of light colours reflecting heat is also achieved. Let's have a look at how this works diagrammatically.

The diagram on the top right shows how a white paint acts to reflect part of the solar radiation to reduce the amount of transmitted heat. Other colours also reflect heat, but the darker the colour, the less the reflection.

The lower diagram shows how an insulating coating acts as a barrier to heat transfer through it, so even without being a light colour the resulting amount of transmitted heat is reduced.

The diagram below shows how a light coloured insulating coating would behave if shown diagrammatically. It can be seen that some of the solar radiation is reflected and the remaining heat load is reduced because of the thermal barrier providing by the insulating coating.

What are some of the Properties of Insulpaint ® ?

• Insulpaint ® has great strength coupled with flexibility

• Insulpaint ® is completely impervious to airborne pollution & extreme weather conditions

• Insulpaint ® is non-flammable, non-toxic & contains no hazardous materials (for example asbestos, glass or mineral fibres)

• Insulpaints has a s standard colour range s but can be tinted to Client requirements

• Insulpaint ® is completely waterproof and yet is micro-porous allowing the substrate to breathe, allowing remarkable stability particularly on concrete. As examples:

1. Tarmac Alawi lab test- Roof flooded with water for 2 days with zero leakage

2. Taywood Engineering conducted water absorption test showed no absorption

Why is the Paint Base so Important ?

The base resin used in the manufacturing of the paint determines the quality of the coating . If a cheap base is used, then the coating will break down prematurely.

• Insulpaint ® resin is 100% Styrene Acrylic Resin (SAR).

• SAR is far superior to any other acrylic resin, combining:

• Superior hardness

• Superior flexibility

• Superior durability

• SAR properties make it ideal for roof coatings.

• Water based allowing easy cleanup.

FREQUENTLY ASKED QUESTIONS

What Should I Paint to get the Best Effect?

From all the information you have read so far, you have probably realised that we keep referring to the painting of the roof . We generally only refer to the painting of the roof because it is the part of the building that receives the greatest solar radiation heat loading. Sometimes there are other parts of the building that would also reduce the building heat loading if painted with Insulpaint ® , for example a large external wall that for most of the day is exposed to the sun. With a little help from your Insulpaint ® distributor you will be able to determine what would be the best surfaces to paint to achieve the greatest reduction in heat loading.

How Thick is The Insulpaint ® Applied?

Generally the Insulpaint ® is applied to a wet film thickness of 0.45 mm.

This Equates To Half a Litre Per Square Metre ie 200 m2 Surface Requires 100Ltrs Insulpaint.

Who can Apply Insulpaint ® ?

Anybody who is a reasonable painter can apply Insulpaint ® , however the instructions must be carefully followed.

What Surfaces can be Painted with Insulpaint ® ?

Insulpaint reduces the internal temperature when applied to the external surfaces of the following substrates:

• Metal

• Tiles

• Brick

• Fibro Sheeting

• Concrete

• Timber

• ASBESTOS

What are some Ideal Insulpaint Applications?

Insulpaint dramatically reduces the solar radiation heat loading when applied to all surfaces such as,

• Roofs on Factories Houses,patios,sheds,Dog and cat kennels,ANY HOT SURFACE!

• Walls on the above and/Concrete Tilt Panels. Concrete Foundation Slabs.

• Site Offices/Metal/ Steel/Asbestos/Wood/ Fiberglass

• Portable Structures/BOATS/ Any surface material.

• Water Storage Tanks/ Wine Vats/HOT Pipes/Railings/Gates/Driveways/ Decking/Pools/Steps/Garage Doors/ Trailers.

How Does Insulpaint ® Compare to In Roof Space Insulation?

The diagram on the right shows two scenarios. The top scenario shows how a building with either no insulation or insulation applied in the roof space allows the entire roof space to heat up. This area can heat up to over 50C on a hot day, requiring that the insulation within the roof work very hard to stop the area under the ceiling achieving the same temperature. If there is no insulation the temperature under the situation is even worse.

The lower scenario shows how the situation is different if the roof has been painted with Insulpaint ® .

Firstly, the light colour reflects a considerable amount of the heat load thus reducing the outside temperature of the roof. Secondly the insulating properties of the Acrad 8 prevent a lot of the heat passing from the outside of the coating to the inside. This results in a dramatically cooler roof space and under ceiling space. Additionally, because the roof space is cooler, when the outside temperature drops off the roof space does not continue to heat the building.

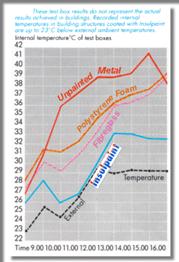

The diagram on the right shows results for Insulpaint ® when compared against the other conventional insulating systems.

Test metal boxes were insulated using the different systems and set outside in the sun. Temperature probes located inside the boxes measured the internal temperatures.

It can be seen that the Insulpaint ® treated box internal temperature was generally within 3C of the ambient (external) temperature.

|

|

This result was far better than both the fibreglass and polystyrene foam insulating systems.

The very top trendline shows a box that was unpainted and uninsulated and reflects the very high temperatures that are achieved if no insulation is used. Remember that this test does not reflect the actual internal temperatures of a building, rather it compares the insulation effectiveness of different insulations.

|

What are some Insulpaint ® Independent Test Results?

CASE 1:

Test Facility: Tarmac LLC

Year of Test: 2000

Result: In Ambient: 40C Average

Double skin insulated wall with 50mm fibreglass - Average 40C

8 inch block wall coated with Insulpaint - Average 35C

CASE 2:

Test Facility: No Boundaries Eng & Science Consultancy

Year of Test: 1996

Result: AE Smith Westair AND Hamersley IronSpecific test result(s) identify the purported 30% to 60% power costs savings.

The ULTIMATE in Insulating Coatings

Thank you for taking the time to read these Information Sheets. Please contact APS or your Insulpaint ® distributor if you have any questions. INSULPAINT AUSTALIA Pty Ltd

Ph: 08 9402 7488

Fax: 08 9402 7477

email Insulpaint-Australia@Insulpaint.com.au

|